Thermographic surveys for insurance providers

Today insurance companies are using thermographic surveys to check the electrical components such as wires, fuses, etc., in the buildings before they insure any property. Electrical fires are commonly linked to damaged or aged electrical equipment. As an insurance provider, it is in your best interest to avoid significant damage from causing any electrical failures. The insurance companies should collaborate with a thermal imaging company like Thermo Elite Inc. as we will help you reduce the risks for your business and clients.

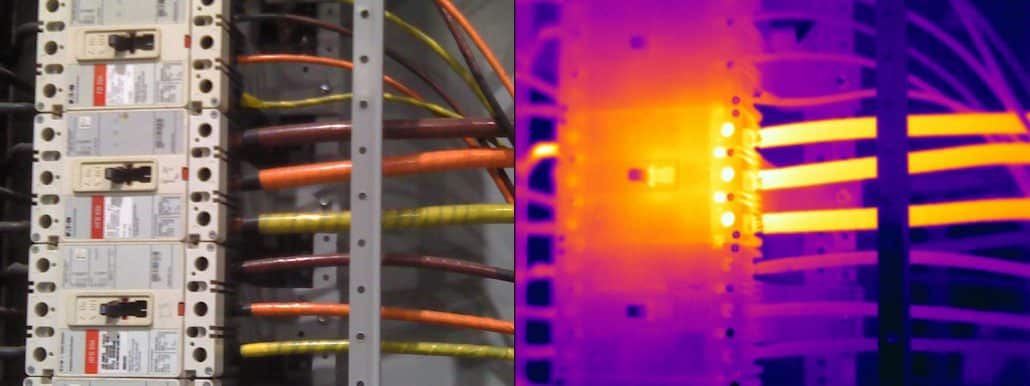

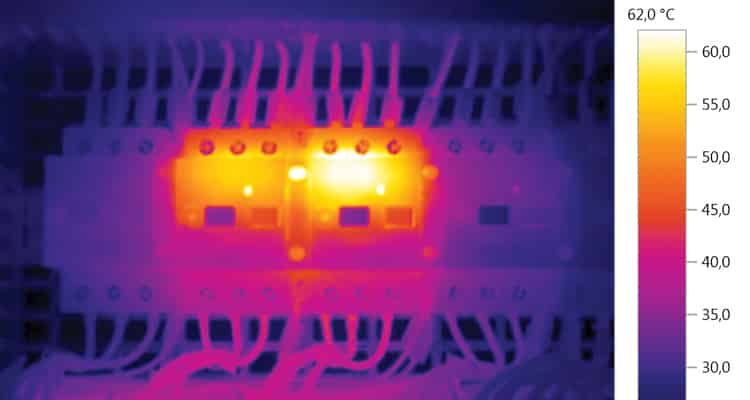

Work with the Thermo Elite Inc. team to keep your existing customers satisfied and draw new ones to your range of services by adding thermographic inspections. Thermography uses infrared video and still cameras to measure surface temperatures. These instruments detect heat spectrum. The temperature differences of the building’s skin are captured in images, ranging from white for warm regions to black for cooler areas, making it much easier to detect the problem. Some of the advantages of working with Thermo Elite Inc. include:

- The thermographic inspection will help you protect your clients by avoiding electrical fires and electrical faults.

- Attract customers with lower premiums if they undergo thermographic inspection

- Get details quickly to start work on claims immediately.

- Our thermographic inspection will help you simplify your work and make estimations easier.

When making estimations or managing claims, thermographic surveys and inspections are beneficial. The electric thermal imaging services we provide are an easy and reliable way to obtain accurate information quickly. It is crucial to have detailed and precise data at your fingertips. Your clients need the information to rebuild their property, and insurance firms need information quickly to start working on claims.

Thermographic surveys for insurance companies

In all electrical aspects, the independent team at Thermo Elite Inc. is experienced. We provide a revolutionary range of thermal imaging diagnostic services to ensure that all electrical components are in good working order and do not pose a risk.

What is a Thermographic Survey?

A thermographic survey is a visual examination conducted by a trained technician to detect abnormally high temperatures within an electrical installation. When the temperature is higher than the average temperature, you can easily find out the system’s problem.

Reasons for abnormal temperature

- Overloaded sockets

- Loose connections

- Faulty equipment

Why is the thermoelectrical survey important?

The most crucial factor of electrical infrared thermography is that you can use it to find any electrical component’s early issues before it completely fails. It is easy to find the problem because of any electrical element’s heat build-up when it works under stress. Unexpected failures of electric components or supply of electricity can be both inconvenient and expensive. Infrared electrical thermography is a handy method for detecting stressed electrical components in your installation until they fail or cause a fire. This allows you to address the issue as part of routine maintenance before it becomes a severe issue.

The risk of fire is another consequence of failed or stressed electrical elements; in reality, the risk is more real than most people realize. Insurance firms are increasingly requesting an infrared thermoelectrical survey as a valuable risk management tool.

Earlier, this service was very costly, and only a few big companies used it. Still, advancements in technology and its availability at lower prices have made Thermo Electrical Survey more common today. Today thermographic surveys have become a very profitable tool for insurance companies as well.

Benefits of Thermo Electrical Survey

Electrical, thermal imaging surveys are non-intrusive, allowing inspections to be performed safely and efficiently while minimizing risk. According to a major insurance firm, faulty electrical connections are responsible for approximately 25% of all electrical failures. As a result, several insurance companies are now reaching out to thermographic companies like Thermo Elite Inc. to perform the annual thermoelectrical survey.

Thermo electrical surveys have evolved into one of the most effective strategies for preventing electrical failures and provide several other benefits as well, and these are as follow:-

- It helps in detecting hot spots such as loose connections and bad contacts.

- You can easily detect those cables that are getting overheated.

- Unbalanced loads.

- Earth leakage units, circuit breakers, conductors, and other electrical components have been stressed.

Benefits for Insurance companies

Compliments the Periodic Fixed Wire Testing:

Electrical thermography detects electrical problems that are difficult to identify during standard wire monitoring and inspections. Periodic Fixed Wire Testing ensures that all the safety devices like fuses and circuit breakers work fine if any short circuit and fault load happens. If these devices are not in good condition, then you won’t get any protection from them.

Once you do the periodic fixed wire testing, you should also perform thermal imaging to know that everything is working fine.

There is no other method that can safely and efficiently detect electrical issues like poor connections, overloading, phase imbalances, defective equipment, and so on. A thermographic survey is non-intrusive and can be carried out quickly. Productivity, profitability, and workplace safety are enhanced by identifying issues and scheduling repairs before a significant failure occurs.

Where can you perform a Thermo Electrical Survey?

There are many areas where you can perform the thermoelectrical survey. Below are several places where you can use this technology:-

- You can use the thermoelectrical survey to detect loose or corroded electrical connections in a building.

- It helps you detect electrical unbalance and overloads.

- Inspecting bearings and Electrical motors.

- Inspecting steam systems IR Imaging helps better to recognize and report suspect elements.

- You can check high resistance connections with the thermoelectrical survey.

- Find hot spots.

- Detect over-loaded cables.

- Overloaded fuses or breakers

- It is an easy method to detect imminent motor or conveyor bearing failure.

- You can use it for phase load imbalance detection.

- With its help, you can easily find the hot spots in high-level lighting.

When you carry out regular thermoelectrical surveys, you can quickly evaluate the performance of electrical distribution systems and electrical components. Any necessary maintenance can be planned as part of a preemptive maintenance strategy.

How infrared thermography works?

Heat is radiated from both electrical and mechanical devices. Temperature variations between surfaces are detected and measured using infrared video cameras that are sensitive to thermal radiation. The information is then converted and shown as a visible image by the cameras, allowing us to “see” a heat signature. Thermal patterns that are abnormal or unexpected usually suggest an issue with the equipment, such as loose electrical connections, overloaded circuits or phases, etc.

By identifying the “hot spots,” a trained professional can easily find the root cause and possible solution.

A trained professional at our company will conduct the Thermo Electrical Survey. A report will be produced that includes detailed information on the items surveyed and faults and recommendations for the best possible solution, or simply to provide peace of mind knowing everything is working correctly.