Infrared thermographic inspections are the latest trend in the home and buildings inspection industry. The infrared thermographic technology is preferred because it is easy to use, and it is precise and accurate. The technology has continued to evolve over the years, and it has become more effective and accurate. However, the accuracy of the infrared thermographic camera to some extent depends on how the user handles it.

In as much as infrared thermographic inspections are not rocket science, especially for homes, you need a certain level of expertise to be able to carry them out. In this article, we are going to explore several ways in which one can ensure they are getting the most accurate results while conducting infrared inspections. Before we get there, let’s just get a quick recap of how infrared thermographic cameras work.

Infrared Imaging Cameras

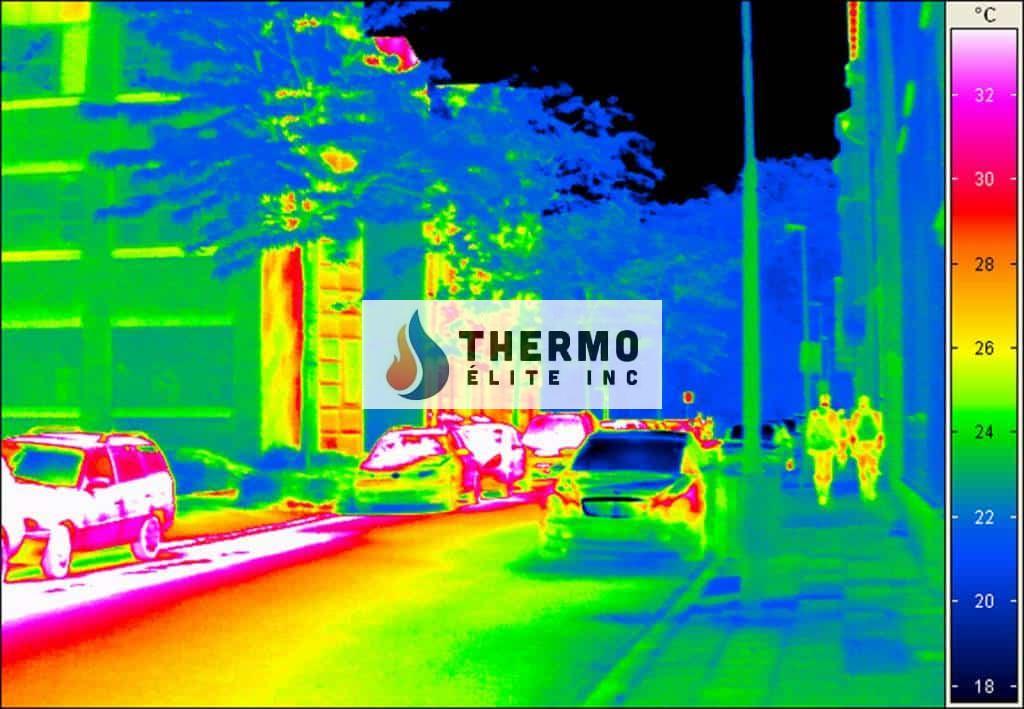

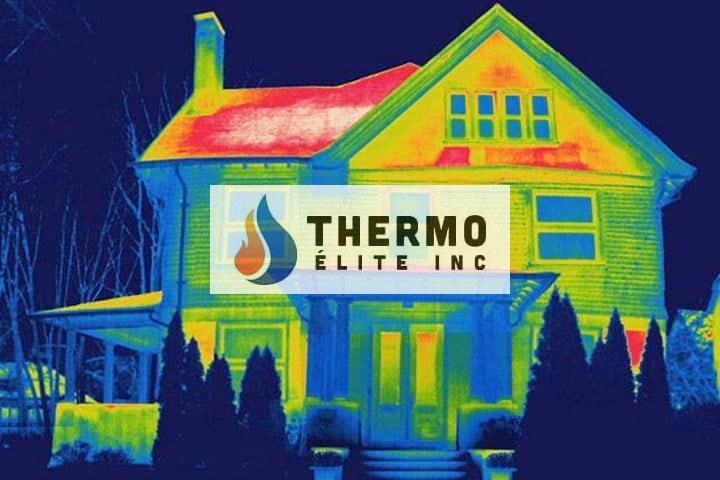

These little gadgets, and sometimes large, are the real deal. They work by capturing infrared rays emitted by various objects. They use this emission to calibrate the temperature of a different object. Infrared inspections are mainly based on temperature differences. Different objects under certain conditions are expected to have certain temperatures. Abnormalities in these temperatures often depict that there might be a problem.

Infrared imaging cameras are mainly handheld, and all you go to do is point them to the object or section you are inspecting. They will feed you back a colored image of the point of view. It is not an exact image of the object, but a heat map. The different colors depicted show the differences in temperatures. These colors enable inspectors to quickly call out abnormalities and take a closer look. The colors range along the wavelength spectrum.

Now let’s get to how you can increase accuracy during infrared inspections.

Get a Quality Camera

We’ve just described how the infrared imaging camera works above. Your inspection can only be as accurate as your camera allows you to be. As the inspector, especially a professional one, you must have a quality camera. The features of a great infrared imaging camera include;

- High sensitivity for heat differences. It should be able to catch even the subtlest heat differences. The whole technology is based on heat differences anyway.

- Clear and sharp images. The heat maps displayed should not leave you guessing. The colors should be sharply contrasted in order to help you easily catch abnormalities.

- It should be able to measure a wide range of temperatures. A good camera has no qualms measuring temperatures as low as 10 degrees Celsius and as high as 380 degrees Celsius.

- The camera should have enough storage for footage and images. These images and footages are what is used to prepare inspection reports. The camera should also have ways to share or transfer these images. Bluetooth, Wi-Fi, USB port are all very essential for the camera.

- Modern cameras are coming with inspection report preparation software. That makes the inspectors’ work quite convenient. He/she can just prepare the inspection report on-site and hand it to the home’s owner. It would be convenient to have such a camera.

All the factors outlined above are basically what you should be looking for when you go looking for an infrared imaging camera. Even is some of them have nothing to do with accuracy, they will allow you to do your work conveniently and hence produce better results. Temperature measurement capabilities and sharp images are the main issues when it comes to accuracy. There are many brands of infrared imaging cameras out there, and you must know what makes a great infrared camera.

While it may seem like a very obvious thing, many inspectors fail to properly prepare their cameras and end up not getting accurate results. Before commencing the inspection, there are some common practices that involve checking the readiness of the camera. It is important to always conduct these checks to ensure your camera is ready to rock and roll. The checks include;

- Ensure the batteries are fully charged. You do not want the camera to go off while in the middle of the inspection.

- Make sure the camera is well calibrated. Modern imaging cameras are just about getting the right settings for the measurement you want.

- Clear the internal memory of the camera of any previous data that might be stored there. You do not want that new data to mix up with data from somewhere else. You would end up with the wrong findings after the analysis.

- If you are going through an inspection route that had been previously inspected, you can upload the past inspection’s data or results. This will help you make comparisons while you move ahead. This practice is quite essential while inspecting an establishment that has undergone repairs after a previous inspection. It helps to ascertain whether all the issues have been solved

- Ensure you line up all the equipment that you are going to need before you commence with the inspection.

- Talk to your workers about using the equipment, the process, and safety if you are working as a team. You need to ensure you are all on the same page.

- Take note of any unusual conditions that might affect the results of the inspection. Weather conditions are often a source of concern during infrared inspections.

Inspection Expertise and Experience

We’ve mentioned before that infrared inspections are not so difficult that you cannot inspect your home yourself. You just need a good camera and an understanding of the basics of the process. However, it makes a lot of difference when you have relevant expertise and experience. That is why professional inspectors exist. Establishments such as factories and large commercial and residential buildings require the attention of trained and experienced inspectors.

The process if not about capturing heat map images. It is also about analyzing the images and being able to make split-second decisions. Focus is therefore very key if you are to ensure accuracy. Inspectors have to remain very focused, which is quite difficult at times, to ensure they do not miss anything. Remember infrared inspections are a non-contact method of inspection. A hurried inspection that does not pay attention to every detail will most likely leave a lot of issues behind.

Experience infrared thermographic inspectors like to manually focus their imaging cameras. They understand the level of detail they are looking for in order to ascertain the condition of various sections of the house. They know how their way around the imaging cameras, and how to get the best out of them. The following are some tips that you could use to ensure you get the best results from your imaging camera.

- You should begin with a monochromatic color palette so that you are able to get human-friendly contrast on the screen. The human eye finds it easy to focus on the greyscale (black and white) or the amber scale (back and yellow) as compared to full-color scales.

- Investigate for sharp edges all over the field of view that is at the same distance as the target and pay attention to that first.

- Imaging cameras that have laser-assisted automated focus are quite ideal in these situations. They ensure better focus and save you some time. The laser distance meter is quite effective in calculating the distance of the target. Give the focus engine some time to focus precisely and sharpen the image for you.

- Modern imaging cameras feature multifocal capture. This allows them to capture and record multiple images from different focal distances. The images are feed to special software that combines them into a single image with more depth and finer details.

Field of View and Resolution

Your field of view determines the resolution you get on the image. A large field of view will have less resolution, and vice versa. High resolution is always desired in order to get finer details. You are supposed to zero in on the Field of View until you get the desired resolution.

The resolution of an image can be measured in two ways. One is the detector resolution which is measured in pixels, and the spatial resolution which is measured in mRads. Every single detector pixel picks up the apparent temperature of the surface it covers on the target. As such, better resolution means more accurate temperature measurements. Spatial resolution helps to define the Field of View. It is used to determine the area on the object that the imager captures at a given moment. These measurements help the inspectors understand the effectiveness of the imaging camera with regard to the size of the objects being investigated. Low spatial resolution value implied better image quality and finer details.

Thermal imaging when done properly with a good quality imaging camera produces some impressive results. It increases your troubleshooting and inspection efficiency as an inspector. Below are some guidelines that are commonly followed in order to enhance that efficiency and keep the workers safe as they interact with various systems.

Thermography-Specific Inspection Process

Processes are very essential, especially in a professional setting. They help maintain standards and consistency. They also offer better chances of getting accurate measurements. Each inspection agency can come up with its own inspection process depending on the equipment and kind of training they have. Below is an outline of the general steps expected in an inspection process.

- The first step is to get organized with every piece of equipment that you are going to need. Get a list of equipment from your Computerized maintained management system (CMMS) if you have one. You can also create your own inventory systems. The equipment needs to be grouped in categories based on either function or area.

- When starting the inspection, some inspectors choose to focus on areas that have a history of faults first. Wherever you start, ensure you have ways to mark the inspected areas. Mark them in a way that you will remember what issues you found there. Keep in mind that a good number of faults in a building are interconnected. When a fault develops somewhere, it often has a cascading effect of causing faults elsewhere and the trends continue until repairs are done. As such, one fault will most likely lead you to another one elsewhere.

- The starting point of the inspection is always the most difficult as you have to figure out the layout of the various systems that you are to inspect. It becomes even more difficult when you do not have a map of the layout. Once you’ve figured out the easiest and safest way to access these systems, the rest of the inspection becomes a breeze.

- During the inspection, you can take actual images of the objects using a digital camera and attach them to the heat map images for the purposes of reporting. You can also record verbal notes or takedown text notes on the camera so that you can recall what those images are about when it is time to do the analysis. Most of the imaging cameras have enough space to store such data. We earlier mentioned that you have to ensure the camera you have has enough storage.

- Expect to encounter a couple of hiccups here and there when you first introduce infrared inspections to your building inspection process. Once you get used to it and understand how it works, the issues will be eliminated one after the other until you have a seamless process. You will then have a chance to reorganize and streamline your processes depending on the kind and condition of the equipment that you have.

The bottom line is, infrared inspections are very accurate and effective if they are done properly. The main things are to have the right equipment, know how to use the equipment, and follow the right processes. Infrared inspections are the main type of inspections in the home and buildings inspection industry today. They provide accurate and reliable results. They also help ensure all faults and impending problems are caught before they actually occur. We could go on and on about the benefits of infrared inspections, but that should probably be a story for another day.