Introduction

When it comes to managing a commercial property, electrical safety and efficiency should be a top priority. Herein, the critical role of commercial electrical inspections comes into play. A leader in this space, Thermo Elite, offers a comprehensive service to ensure your electrical systems are in tip-top shape, which is essential to your safety, cost-effectiveness, and longevity of the systems.

The Value of Commercial Electrical Inspections

The benefits of commercial electrical inspections extend far beyond a simple tick on your maintenance checklist. Thermo Elite’s inspections offer three significant advantages: the identification of electrical safety hazards, the potential for energy cost savings, and an increase in the lifespan of your electrical systems.

Ensuring Safety

Ensuring Safety

One of the core aims of commercial electrical inspections is to ensure safety. Electrical hazards can cause serious harm or even be fatal, not to mention the potential for property damage. Thermo Elite’s inspections identify such hazards before they become a major problem. This proactive approach keeps your employees, clients, and property safe.

Saving Energy Costs

Efficiency is a key factor in managing the energy costs of a commercial property. With Thermo Elite’s inspections, potential energy leaks and inefficient systems are identified. By rectifying these, you can significantly lower your energy bills, making your property more cost-effective and eco-friendly.

Increasing Lifespan of Electrical Systems

The longevity of your electrical systems is another important consideration. Frequent inspections by Thermo Elite can identify minor issues before they escalate into major problems that can damage your system. Regular maintenance means a longer lifespan for your systems, saving you from the substantial costs associated with replacements.

Thermo Elite’s Inspection Process

Thermo Elite stands apart in its commitment to an advanced, thorough, and professional inspection process. Its team of highly experienced professionals uses cutting-edge technology to provide an unparalleled service.

Experienced Professionals

Experienced Professionals

Thermo Elite’s team comprises seasoned professionals with years of experience in the field. These experts understand the intricacies of commercial electrical systems and know exactly what to look for during an inspection.

Advanced Technology

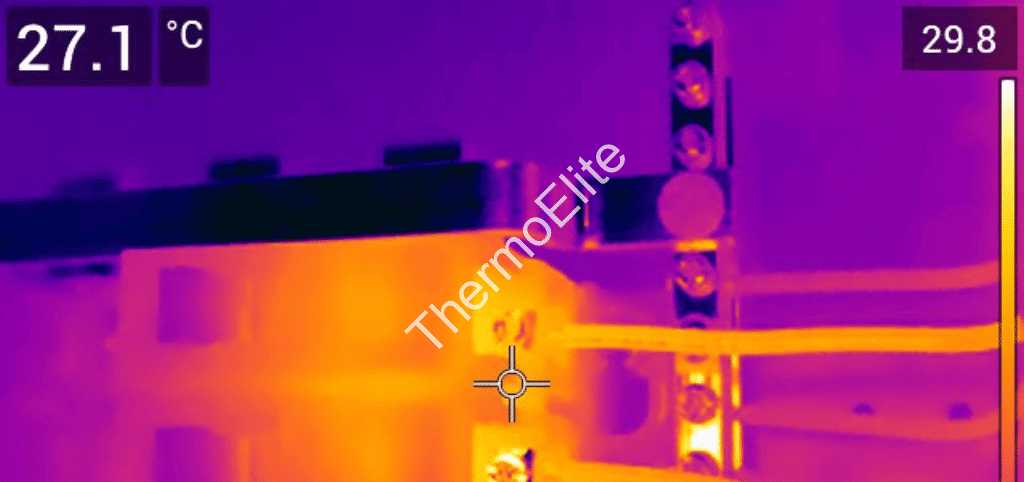

Thermo Elite employs the latest technologies in its inspections. With tools like infrared thermography, professionals can identify potential issues that may not be visible to the naked eye. This allows for the detection of issues like overheating components, which can be a precursor to electrical failure or fire.

Meeting Industry Standards

In addition to providing top-tier service, Thermo Elite’s commercial electrical inspections meet and often exceed industry standards. They are committed to complying with all relevant regulations and norms, providing peace of mind for their clients. Thermo Elite is also proudly accredited by recognized bodies, further showcasing their dedication to providing a professional, reliable, and high-quality service.

Conclusion

The importance of regular commercial electrical inspections cannot be overstated. Thermo Elite’s services offer a comprehensive approach to safety, cost savings, and longevity of your electrical systems. With a highly experienced team and the use of advanced technology, Thermo Elite provides a top-tier service that meets industry standards and accreditations. When it comes to commercial electrical inspections, Thermo Elite truly shines in its commitment to the safety and satisfaction of its clients.

Ensuring Safety

Ensuring Safety Experienced Professionals

Experienced Professionals