Thermographic inspections are like having superhero vision for modern industries! They use infrared tech to see heat patterns and energy flows, spotting problems that our eyes can’t. This article is going to chat about why they’re so cool and useful.

So, What’s Thermographic Inspections All About?

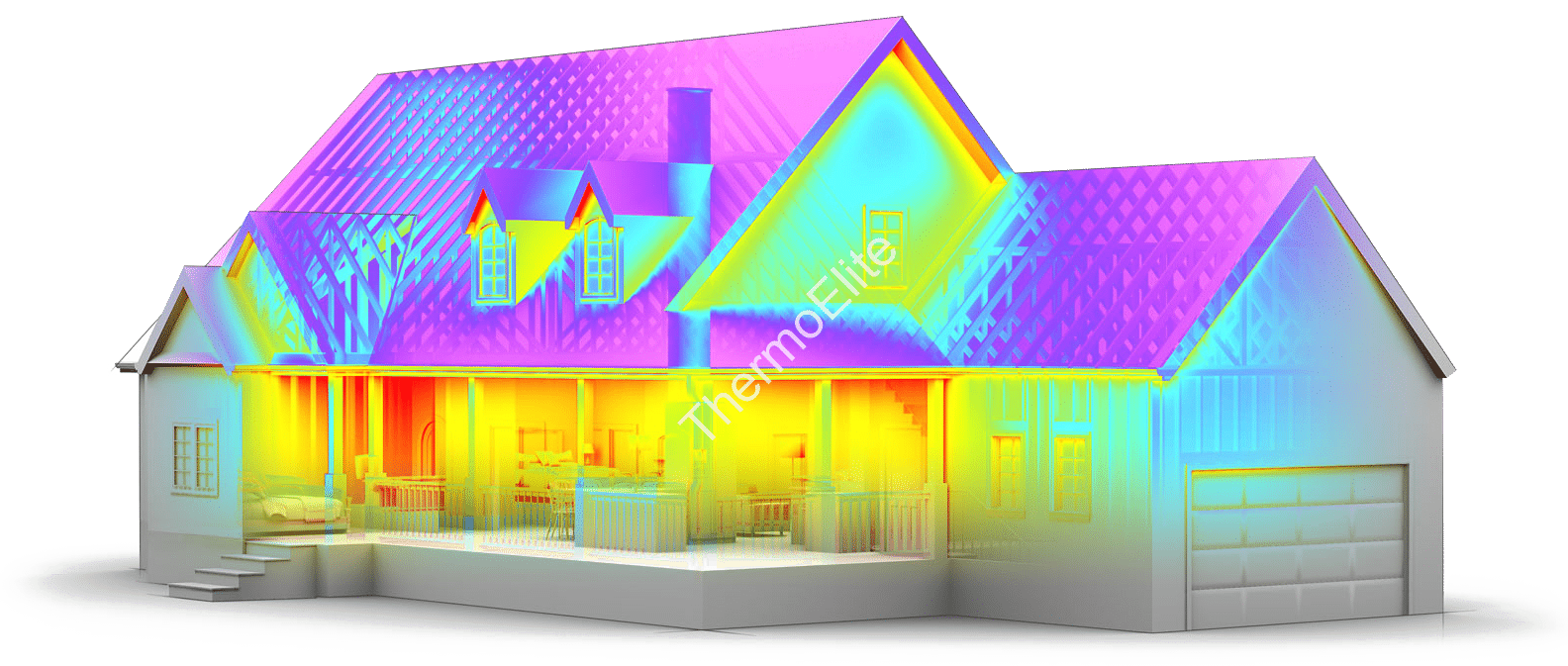

Imagine you have special goggles that let you see temperatures. That’s basically thermography. These special cameras pick up infrared energy (which comes off everything depending on how hot or cold it is) and turn it into a picture showing temperature differences. This is super handy because it can spot issues like electrical problems, missing insulation, or parts of machines wearing out, all without having to take anything apart.

Where Do We Use This Awesome Tech?

- Electrical Stuff: In places with lots of wires and circuits, electrical thermographic inspections can find hot spots that might mean there’s a problem like bad wiring or something overloaded. Catching these early can stop big accidents, like fires.

- Buildings: Checking out buildings with these cameras can show where heat’s escaping or if there’s unwanted moisture. This is great for making places more energy-efficient and stopping stuff like mold.

- Machines: For all sorts of equipment, thermography can spot parts that are getting too hot, which might mean they’re about to break. Fixing things before they break is way cheaper and causes less downtime.

- Health and Animals: Even doctors and vets use this tech! It can show up things like inflamed areas on a person or help find injuries on animals, all without having to poke and prod.

Why is Thermography Super Useful?

- It’s Like X-Ray Vision: You can see problems without having to take anything apart or touch it, which is safer and less likely to break stuff.

- Saves Money: Finding problems early means fixing them before they turn into expensive disasters.

- Super Quick: These cameras can scan big areas fast, so they don’t slow down normal work.

- Paperwork Helper: The images you get are great for showing you’re following safety rules and keeping track of things over time.

What’s Next for Thermography?

The future looks bright (in infrared, anyway!). As cameras and software get better, these inspections will get even more accurate. We might see drones flying around doing big scans, and AI helping to figure out what the pictures mean. Plus, as everyone’s trying to be more eco-friendly, using thermography to cut down on energy waste is going to be a big deal.

In a Nutshell

Infrared Thermographic inspections are a game-changer. They’re like having superpowers for spotting problems in all kinds of places, from factories to hospitals. They keep things running smoothly, save money, and even help the planet. As tech gets better, they’re only going to get more important. They’re not just about fixing stuff – they’re about moving forward with smart, safe, and green solutions.

Add Comment