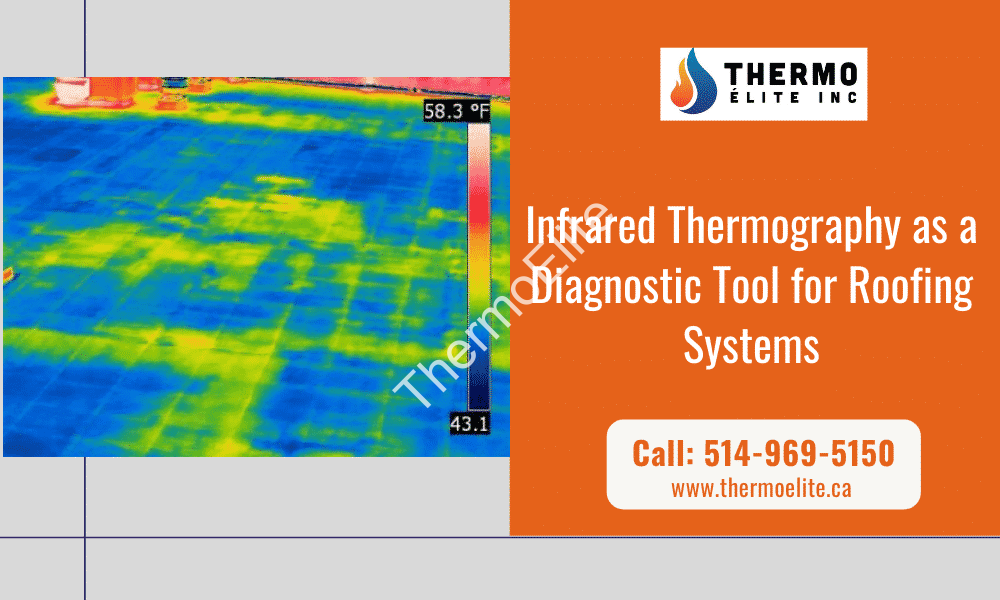

Infrared thermography has become a common inspection technique for detecting latent moisture in flat and low-slope roofing systems. Thermography is commonly used for condition assessments, forensic investigations, and quality assurance inspections of new installations, repairs, and retrofits. Regular infrared scanning of your roof is a cost-effective way to track the condition of your roof and fix problems like wet insulation remediation as soon as possible when they are still reasonably easy to repair. When the inspection is performed by an experienced inspection team, you can get valuable insights into the condition of a roofing system. Using thermography you can get the digital infrared images of the roof that highlights the extent and location of subsurface moisture within a roof.

Thermal imagers, also known as infrared cameras, are used in infrared roof inspections to detect, view, and record thermal patterns through the roof’s surface. The roofing system must have an insulating deck or insulation sandwiched between the roof deck and the waterproofing membrane to be successful.

In this case, the insulation must be in constant contact with the membrane’s underside. Built-up and single-ply roofing systems can also use thermal imaging. Thermal imaging can be used on coated or uncoated spray-applied polyurethane roofing systems with success.

How it Works

The thermal properties of an insulated roof are changed by water inside the insulation, which are known as thermal conductivity and thermal capacitance. Since roofing systems do not generate heat as a byproduct of their regular operation, changes in thermal capacitance or thermal conductance can be exploited by carefully conducting the infrared inspection.

When the climate is cool where roofs get considerable amount of solar loading, thermographic inspection often relies on thermal conductivity to drive the survey. Water in roof insulation then causes higher thermal conductivity. When the thermal conductivity is high, it will allow excess heat flow through the roof when there will be a significant temperature variations between the air below the roof deck and outside air.

Thermographers use thermal capacitance to conduct their inspections in hot weather. Wet insulation can retain and store heat during the daylight hours on a sunny day due to its higher mass. When the roof cools down during the evening time, area of the roof containing wet insulation will cool more slowly than those with dry insulation. Due to this reason it will make a warm thermal patterns linked with wet insulation to be detectable for up to several hours after sunset. During the inspection, a thermal imager is maneuvered around the roof in an ordered manner during an infrared inspection.

Some benefits of such an inspection are:

- Finding potential hazards of wet insulation.

- If necessary, schedule repairs to avoid further deterioration.

- Quick changes can increase the lifespan of your roofing device.

- Keep your roof warranty from being voided.

What are the tools used for thermographic roof inspection?

Thermographic roof inspections are carried out with thermal imaging cameras also known as IR cameras. High-resolution Infrared thermal imaging cameras detect trapped moisture in the roof. Wet areas are defined and labeled to indicate where tactical repairs should be performed. Once the wet sections are known you can easily repair them without any need of repairing the whole roof.

How infrared surveys are performed

The sun’s energy heats the roof membrane and the insulation under it throughout the day. When the day progresses into evening and sun sets, the roof structure will cool down and the wet areas of insulation will retain more heat than the dry areas. The inspection team will take pictures of the roof surface using an IR camera and use those pictures to identify problem areas on the roof that are not visible to naked eyes from the surface.

Who can perform a roof inspection?

You preferably want a level two certified thermographer to perform such an inspection, if you contact Thermo Elite Inc. you will find just that. The use of thermal images to diagnose and repair a roof issue requires the expertise of a qualified specialist.

Advantages of infrared inspections for roofing systems

The advantages of using thermal imaging instead of another survey type in terms of expense, time, and accuracy are numerous.

- Detects issues that aren’t visible to the naked eye.

- Since it is a non-destructive technology, your roof structure will not be harmed.

- Because of advanced methods and a short survey period, it is cost-effective.

- Roof replacement is expensive. Regular infrared inspection of your roof is a cost-effective way to track the health of your roof and fix problems as soon as possible when they are still reasonably easy to repair.

Determining the Extent of Damage

Infrared scanning is a non-invasive technique for detecting leaks and determining the level of water damage to the insulation layer underneath. Insulation that is less saturated retains less heat and shows up as graduated color changes on a thermographic image. The most significant advantage of this method is that it eliminates the need to break through the roof to determine how much insulation needs to be replaced.

Add Comment